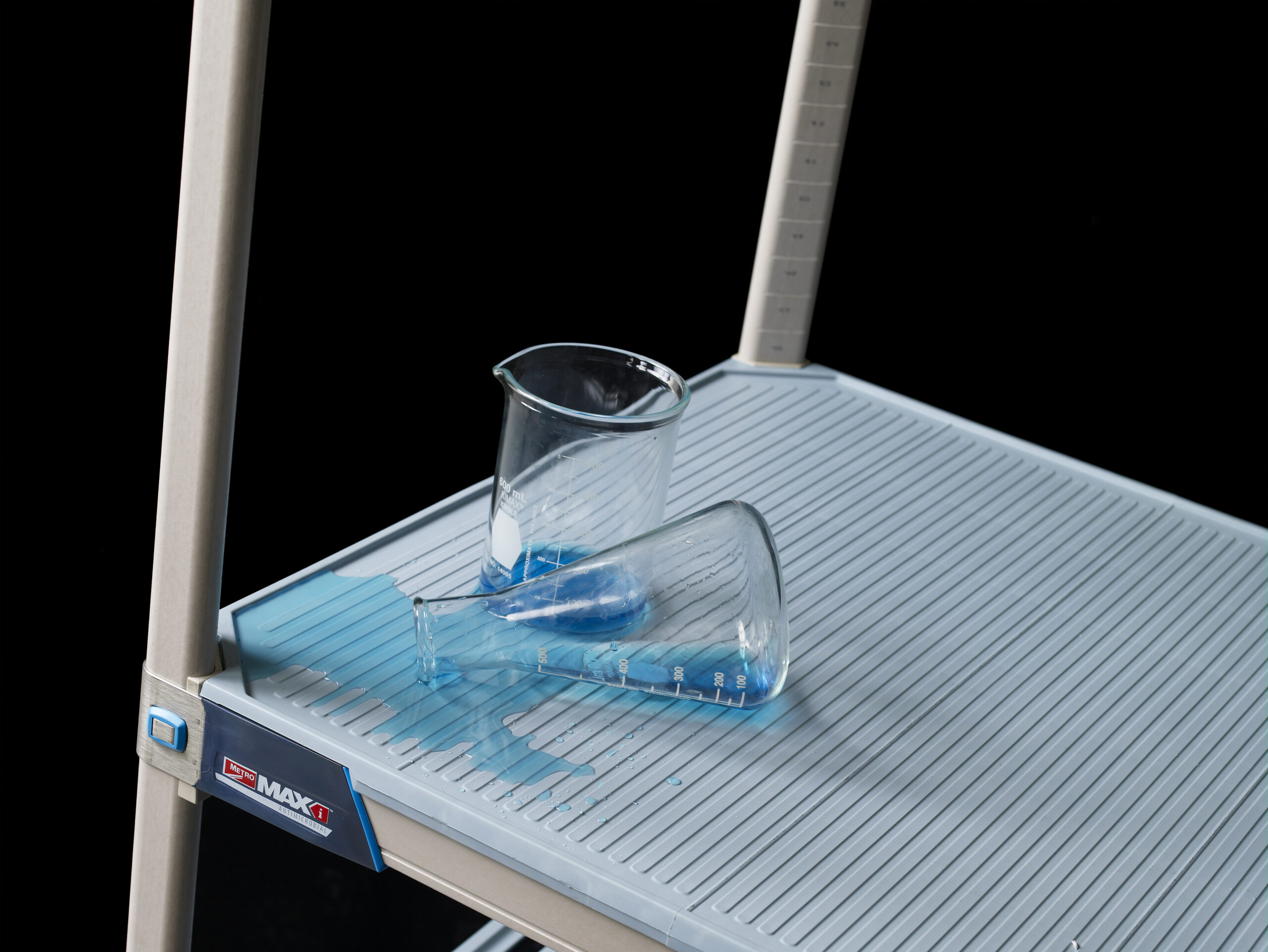

Yes, the initial cost of polymer shelving is more expensive than chrome or stainless shelving, however, in certain situations it will likely save you money in the long run. Polymer carts will outlast their chrome and even stainless counterparts, they don’t rust, they reduce wrap and packaging tears and even the potential for staff injury. That last one isn’t meant to scare. It’s rare, but it can happen.

Sharp edges and burrs both exist on wire units and, to a certain degree, are deemed within manufacturer tolerances. Simply put, they’re a fact of life with wire. This doesn’t mean you should run out and replace your wire carts with polymer but there are several cases in which polymer shelves can improve your bottom line.

Even considering the cost difference (polymer shelving runs about 40% more price-wise than wire), factoring in just a single packaging tear per month from one wire shelving unit brings the cost of ownership of that wire unit on par with the same configuration in polymer.

Multiply that savings through a whole department and consider how that amount of money could get redirected back towards patient care. Extend that over the 7, 10 or even 15 year life span of a cart and the savings measures well into the thousands. That makes the initial cost of polymer worth considering.

Polymer shelving is great for other applications as well.

With a lifetime warranty against corrosion it is a great alternative to stainless steel shelving in fridges and freezers.