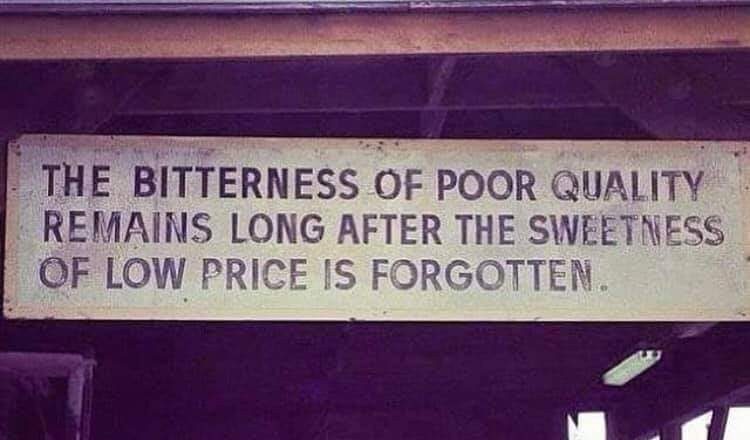

Storage and carts might not be the first things that pop into your head when thinking about saving money in healthcare, but we think there’s something to it.

Recent data from the Canadian Institute for Health Information (CIHI) shows that the largest single expense for Canadian hospitals is employee compensation. The CIHI reports that labour costs account for over 63% of all expenses. And the private sector is booming, with privatized clinics in Canada seeing increases in patients as people are fed up with wait times in the public system. And here’s the kicker: Canada is in the throes of a healthcare labour crunch as a result of unprecedented levels of burnout, absenteeism, and turnover, and it’s entirely possible our contract labour expenses for private facilities go the way of our US friends, who’ve just witnessed a 258% increase in labour costs due to human resource shortages in the industry.

Simply put, hospitals, along with all types of medical facilities and clinics, are looking for ways to reduce labour costs without negatively impacting patient outcomes. To help accomplish this, they’re exploring efficiencies in supply storage and on-site transport systems. This is where Forsyth Healthcare – Canada’s premium provider of cart and storage solutions – can really help. Below is a breakdown of how carefully curated storage systems and carts can lower your labour spend.

4 Ways Custom Cart and Storage Solutions Can Help Reduce Healthcare Labour Costs While Improving Patient Outcomes

Cleaning and Sanitization Made Easy

Forget the plastic bins: Research continues to demonstrate that typical cleaning doesn’t actually sanitize reusable plastic containers and bins as well as it should. When healthcare facilities switch to wire shelving and wire carts (finished in chrome, stainless steel, and polymer), they can kick plastic bins entirely, which removes the need for nursing staff to constantly clean them out of fear of contamination. Of course wire carts and shelving need to be cleaned periodically, but the time needed to do so pales in comparison to the workload required for reusable plastics. Eventually, the cost savings (by switching) will add up big time.

Improved Infection Control

Infections are no joke. And neither are the clinical and economic burden of healthcare-associated infections, including extended lengths of hospital stays, which increases labour requirements. Infection control is not only a key to improving patient outcomes but to reduce labour costs. The CDC outlines seven basic principles of infection control:

- Hand hygiene

- Use of personal protective equipment (e.g., gloves, masks, eyewear).

- Respiratory hygiene / cough etiquette.

- Sharps safety (engineering and work practice controls).

- Safe injection practices (i.e., aseptic technique for parenteral medications).

- Sterile instruments and devices.

- Clean and disinfected environmental surfaces.

Invest in custom cart and shelving solutions that meet CSA standards such as Z314.15 and factor each one of these principles as they protect medications, equipment, and supplies in storage, in transport, and when in use in ORs and other patient care settings. Shelf units should be non-porous and non-shedding, easily cleanable and free from burrs and sharp edges. Procedure carts and cabinets like Flexline, Lifeline and Starsys have Microban protection built right into the material. Or, consider a copper finish bacterial protection on high-touch equipment like IV poles and patient stretchers. Ask us about Pedigo’s Cuverro bactericidal copper surfaces.

Smart Inventory Management

Inventory management can be an absolute headache for staff. It can drive up hours, and can add to healthcare facility costs in other ways. Without proper storage solutions, staff can’t properly monitor for shortages and excess. The concerns around shortages are obvious, but the excess can also be a problem when shelves and bins are over-stocked. This leads to an increased risk of supplies falling off of storage carts and subsequently being damaged and/or contaminated. And of course, poorly managed supply inventory can result in outdated/expired materials. Forsyth Healthcare storage solutions that offer better organizing, clear visibility, and optimized dispensing will improve inventory management and take a load off of staff so that they can focus on what matters most – patient care!

Improved Time Management

When our team at Forsyth is planning to renovate or improve a space, we don’t just look at the storage modality, but how users interact with it, approach it, and move within the space. Shelving systems, storage workstations, mobile supply + transport carts, and utility carts (that make supplies more visible and accessible without the need to manipulate drawers or carts on a track) save time, which ultimately saves labour costs (and just makes things easier for staff). We believe that reduced time stress can increase workplace positivity, improve staff movement and productivity, and can reduce the risk of workplace injury (and all the costs associated with lost manhours and workers’ compensation), too.

Why Choose Forsyth Healthcare for Your Storage and Carts Purchases

We hope that the above analysis helps affirm that investing in better storage and carting is crucial, not only to impact labour costs, but ultimately patient outcomes, too. This said, we’re sure you have more questions around shipping, customization, and budgets. This is where Forsyth Healthcare stands out above the rest when it comes to procurement of medical equipment. We’re here to take the guesswork and hard work (assembly, etc.) off of your hands so that you can put your investments to immediate use to the benefit of your staff, patients, and bottom line.

Contact us today for a friendly conversation about how we can create simple solutions that deliver remarkable outcomes for you.